The energy-saving characteristics of vacuum solenoid valves: The selection of high efficiency

Vacuum solenoid valves, as a crucial control component, have extensive applications in the field of industrial automation. With the concept of energy conservation and environmental protection deeply rooted in people's minds, the energy-saving characteristics of vacuum solenoid valves have received increasing attention. In practical applications, how to select highly efficient and energy-saving vacuum solenoid valves has become an important issue faced by engineers. This article will discuss the relevant content of vacuum solenoid valves from two aspects: energy-saving characteristics and high-efficiency selection.

**I. Energy-saving Characteristics of Vacuum Solenoid Valves**

**1.1 Energy Consumption Analysis**

In industrial production, vacuum systems usually require a large number of vacuum solenoid valves to control the gas flow. Therefore, the energy consumption issue of vacuum solenoid valves has become the focus of engineers' attention. Traditional vacuum solenoid valves generate significant energy consumption during operation, which not only increases production costs but also is not conducive to energy conservation and emission reduction. Therefore, choosing energy-saving vacuum solenoid valves is particularly important.

**1.2 Energy-saving Principles**

Energy-saving vacuum solenoid valves typically adopt advanced control technologies and materials to reduce energy consumption by optimizing the structural design and reducing internal resistance. For example, using advanced electromagnetic materials and optimizing the coil design can reduce the power consumption of the solenoid valve; using advanced sealing materials and lubrication technologies can reduce internal leakage and improve sealing performance, thereby reducing energy consumption.

**1.3 Energy-saving Effects**

Selecting energy-saving vacuum solenoid valves can significantly reduce system energy consumption, improve production efficiency, and reduce production costs. According to statistical data, after adopting energy-saving vacuum solenoid valves, system energy consumption can be reduced by more than 10%. For large-scale industrial production systems, this will bring considerable energy-saving effects and economic benefits.

**II. High-Efficiency Selection**

**2.1 Performance Indicators**

When selecting vacuum solenoid valves, in addition to energy-saving characteristics, their performance indicators also need to be considered. For example, response speed, sealing performance, pressure resistance capacity, etc. are all important factors affecting the performance of vacuum solenoid valves. High-efficiency selection requires comprehensive consideration of these performance indicators to find the product that is most suitable for actual application requirements.

**2.2 Technological Innovation**

With the continuous advancement of science and technology, the field of vacuum solenoid valves is also constantly undergoing technological innovation. For example, adopting advanced intelligent control systems can improve the response speed and accuracy of vacuum solenoid valves; adopting advanced materials and processing techniques can improve the sealing performance and pressure resistance capacity of vacuum solenoid valves. Therefore, during high-efficiency selection, it is necessary to pay attention to whether the product has the latest technological innovation and superior performance.

**2.3 Adaptability Analysis**

Different industrial applications have different requirements for vacuum solenoid valves. Therefore, adaptability analysis is required during selection. For example, some special working conditions require vacuum solenoid valves with special properties such as corrosion resistance and high-temperature resistance; some high-frequency switching occasions require vacuum solenoid valves with special properties such as fast response and wear resistance. Therefore, during high-efficiency selection, adaptability analysis needs to be carried out based on actual application requirements to find the most suitable product.

**III. Conclusion**

In conclusion, as an important control component in the field of industrial automation, the energy-saving characteristics and high-efficiency selection of vacuum solenoid valves are of great significance for energy conservation and emission reduction and production efficiency improvement in industrial production processes. In actual selection, engineers need to comprehensively consider factors such as the energy-saving characteristics, performance indicators, technological innovation, and adaptability analysis of the product to find the most suitable product for their own needs. It is believed that with the continuous progress of science and technology and the continuous improvement of engineering technology, vacuum solenoid valves will have more breakthroughs and innovations in energy-saving characteristics and high-efficiency selection, bringing more convenience and benefits to industrial production.

Product recommendation.

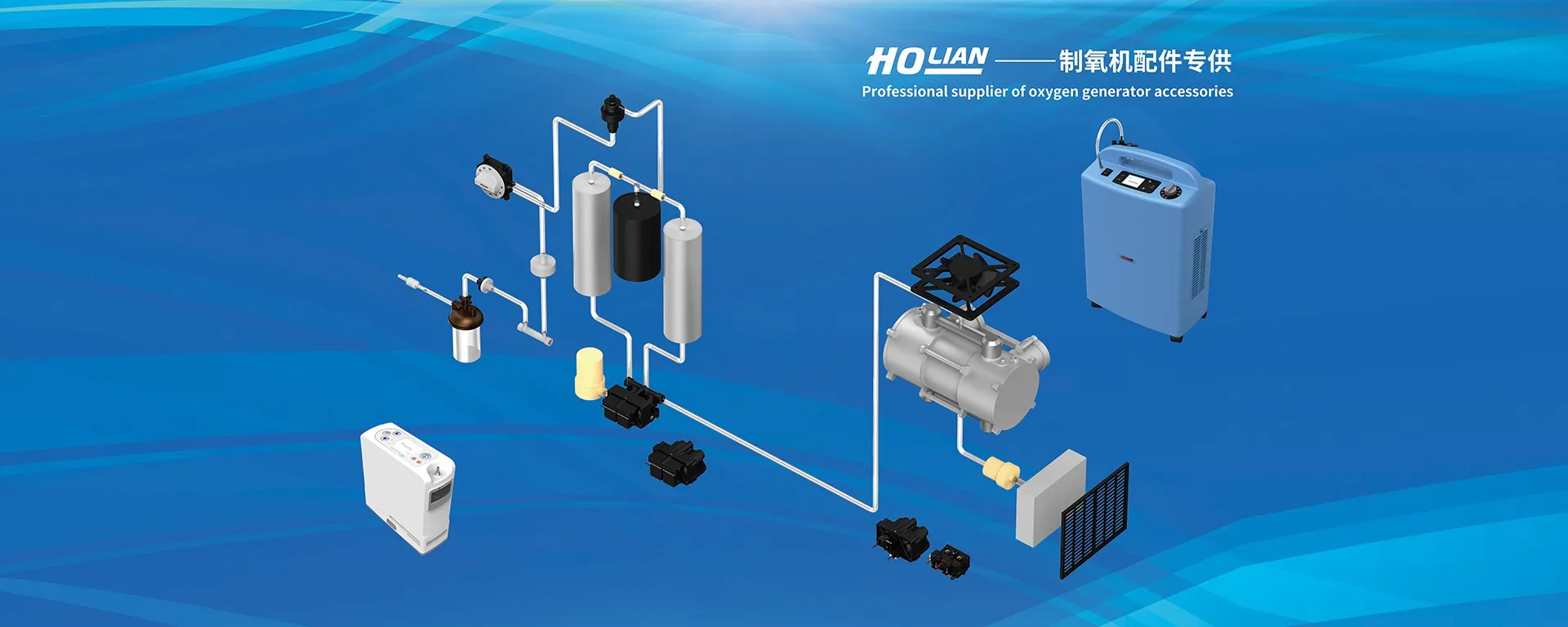

We accept OEM custom products all made in China.Select high quality Oxygen Concengtrator Solenoid Valve products in best price on Shenyang Holian Precision instrument Co.,Ltd.

About us.

Shenyang HOlian Precision instrument co.,Ltd founded in 2017,is specialized production of oxygen generator accessories :Miniature solenoid valve for Portable Medical oxygen generator,4 Way 2 position Medical oxygen generator,3L to 10L Medical Oxygen Generator Solenoid Valve,pressure regulator assembly for oxygen concentrator,Pressure reducing Assembly for oxygen concentrator,Pinhole flowmeter of oxygen concentraror,Pinhole flowmeter of Medical oxygen concentrator,5L flowmeter for oxygen concentrator,Special firesafe Valve for oxygen concentrator,Firesafe Cannula Valve Oxygen Supply Tubing Connector,Oxygen primary filter,Medical Grade Filter,Check valve (material PA6),Check valve (material ABS),Oxygen generator accessories Molecular sieve tank head,Oxygen Concentrator Accessories Air Filters,Oxygen Concentrator Accessories NPT1/8-∅8 Connector,Oxygen Concentrator Accessories NPT1/8-∅10 Connector,Oxygen Concentrator Accessories 3 way Nozzle,Oxygen Concentrator Accessories 90° Nozzle,Mold manufacturing and i jection molding.