How to install the solenoid valve

The solenoid valve has a sealed cavity with through holes at different positions. Each hole leads to the oil pipe of a different solenoid valve. In the middle of the cavity is the valve, and on both sides are two electromagnets. Whichever side of the magnet coil is energized, the valve body will be attracted to that side. By controlling the movement of the valve body to block or expose different oil drainage holes, while the oil inlet hole is always open, the hydraulic oil will enter different oil drainage pipes, and then the piston of the cylinder is pushed by the pressure of the oil. The piston drives the piston rod, and the piston rod drives the mechanical device to move. In this way, mechanical movement is controlled by controlling the on and off of the current of the electromagnet.

Precautions for solenoid valve installation:

1. When the solenoid valve is used in the pneumatic system and connected with pneumatic components, raw material tape (i.e., sealing tape) is generally wound; it is also wound to achieve the sealing function. But experienced friends will surely encounter such a phenomenon: clearly it is a brand-new component, but why does it always leak air during the test run. One of the major and most common reasons for this.

2. When the solenoid valve is used in the pneumatic system and connected with pneumatic components, raw material tape (i.e., sealing tape) is generally wound. It is also wound to achieve the sealing function. But experienced friends will surely encounter such a phenomenon: clearly it is a brand-new component, but why does it always leak air during the test run. One of the major and most common reasons for this is that when the raw material tape is wound, the correct method is not followed, and some of the raw material tape goes into the air circuit; this requires paying attention to the positive and negative sequence when winding the raw material tape. Please apprentices test and experience this point by yourselves.

3. For solenoid valves with large current, relays must be installed at the front end; especially for solenoid valves in the oil pressure system, because of the large current, if relays are not installed, the lifespan of this solenoid valve will be very short.

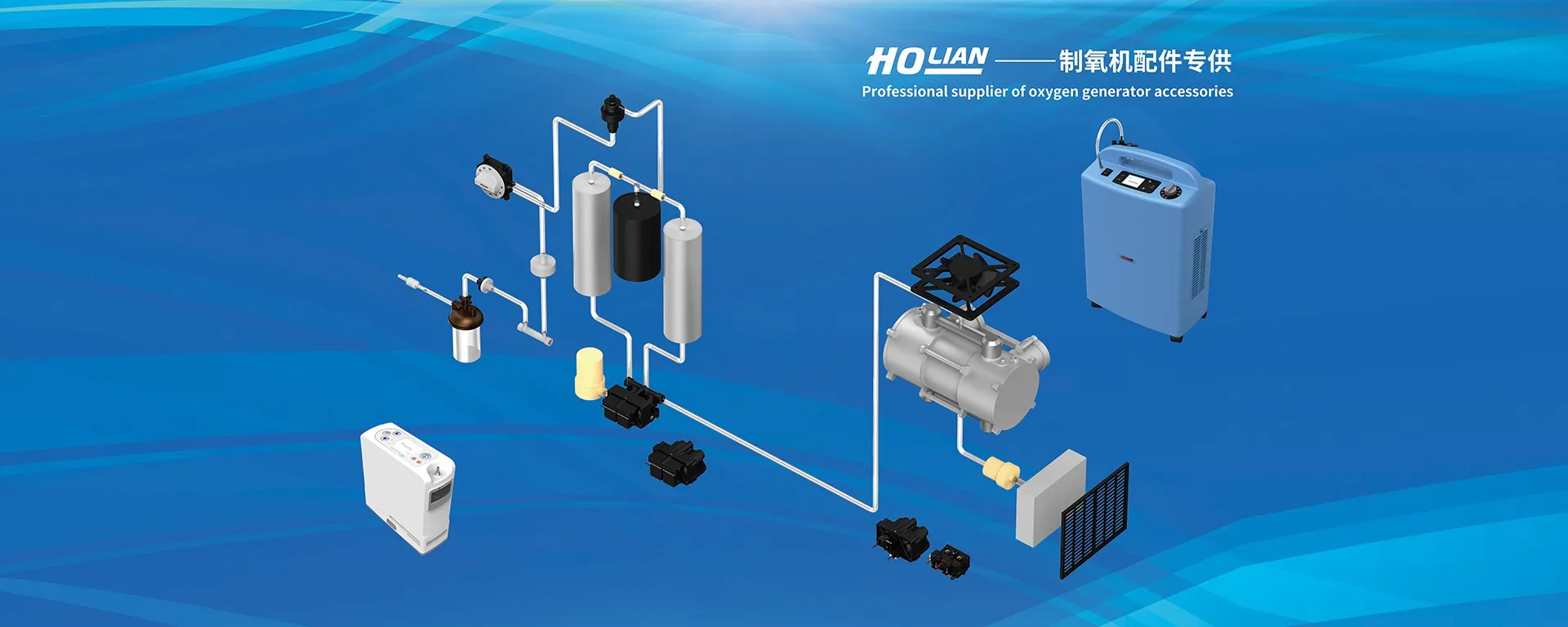

Product recommendation.

We accept OEM custom products all made in China.Select high quality Oxygen Concengtrator Solenoid Valve products in best price on Shenyang Holian Precision instrument Co.,Ltd.

About us.

Shenyang HOlian Precision instrument co.,Ltd founded in 2017,is specialized production of oxygen generator accessories :Miniature solenoid valve for Portable Medical oxygen generator,4 Way 2 position Medical oxygen generator,3L to 10L Medical Oxygen Generator Solenoid Valve,pressure regulator assembly for oxygen concentrator,Pressure reducing Assembly for oxygen concentrator,Pinhole flowmeter of oxygen concentraror,Pinhole flowmeter of Medical oxygen concentrator,5L flowmeter for oxygen concentrator,Special firesafe Valve for oxygen concentrator,Firesafe Cannula Valve Oxygen Supply Tubing Connector,Oxygen primary filter,Medical Grade Filter,Check valve (material PA6),Check valve (material ABS),Oxygen generator accessories Molecular sieve tank head,Oxygen Concentrator Accessories Air Filters,Oxygen Concentrator Accessories NPT1/8-∅8 Connector,Oxygen Concentrator Accessories NPT1/8-∅10 Connector,Oxygen Concentrator Accessories 3 way Nozzle,Oxygen Concentrator Accessories 90° Nozzle,Mold manufacturing and i jection molding.