Comparative analysis: Advantages and disadvantages of direct-acting and pilot-operated solenoid valves

Solenoid valves play a crucial role in industrial control systems. They achieve precise control of the system by controlling the flow of liquids or gases. In the design of solenoid valves, direct-acting and pilot-operated are two common structural types. Each of them has some advantages and disadvantages. This article will conduct a comparative analysis of these two types of solenoid valves so that engineers can choose the appropriate type in practical applications.

The direct-acting solenoid valve is a relatively simple structure. Its working principle is that the electromagnet acts directly on the valve core to achieve control of the valve. This structure has the advantages of simple structure and fast response speed, and is suitable for occasions with high response speed requirements. In addition, since it acts directly on the valve core, the direct-acting solenoid valve can reduce pressure loss to a certain extent, thereby saving energy. However, the direct-acting solenoid valve also has some disadvantages. For example, in occasions with large flow and large diameter, a larger electromagnet is required to achieve control of the valve, thereby increasing cost and power consumption.

Compared with direct-acting solenoid valves, pilot-operated solenoid valves have better performance in some specific occasions. The pilot-operated solenoid valve controls the opening and closing of the main valve through an auxiliary valve, so that precise control of large-diameter and large-flow valves can be achieved. This structure can reduce the size of the electromagnet, reduce cost and power consumption. At the same time, the pilot-operated solenoid valve can also achieve rapid closing and slow opening of the valve, thereby reducing hydraulic shock and noise. However, pilot-operated solenoid valves also have some disadvantages. For example, the response speed is relatively slow and it is not suitable for occasions with high response speed requirements.

In conclusion, direct-acting solenoid valves and pilot-operated solenoid valves each have some advantages and disadvantages. In practical applications, it is necessary to choose according to specific working conditions. If high response speed is required and the flow rate and diameter are small, a direct-acting solenoid valve can be selected; if precise control of large-flow and large-diameter valves is required and a slightly slower response speed can be accepted, a pilot-operated solenoid valve can be selected. Of course, when making a specific choice, factors such as cost, power consumption, and maintenance also need to be considered in order to select the most suitable solenoid valve type.

Product recommendation.

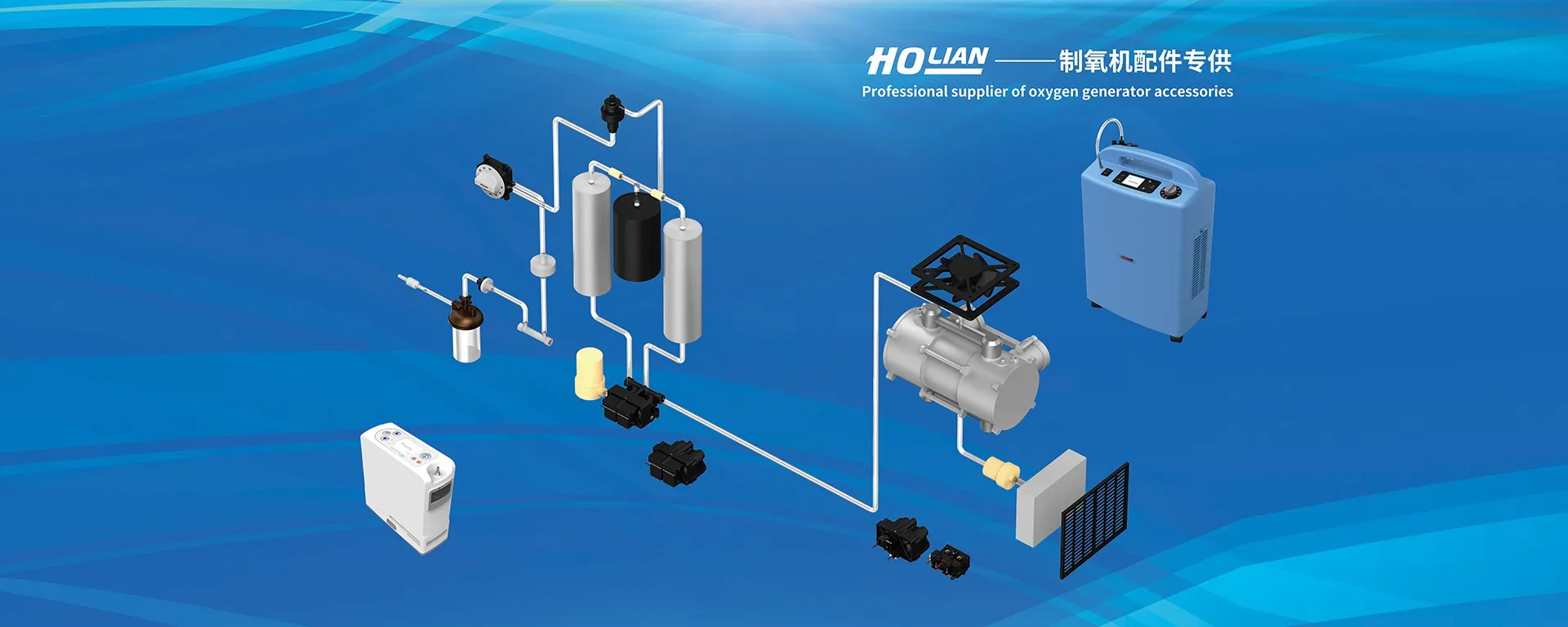

We accept OEM custom products all made in China.Select high quality Oxygen Concengtrator Solenoid Valve products in best price on Shenyang Holian Precision instrument Co.,Ltd.

About us.

Shenyang HOlian Precision instrument co.,Ltd founded in 2017,is specialized production of oxygen generator accessories :Miniature solenoid valve for Portable Medical oxygen generator,4 Way 2 position Medical oxygen generator,3L to 10L Medical Oxygen Generator Solenoid Valve,pressure regulator assembly for oxygen concentrator,Pressure reducing Assembly for oxygen concentrator,Pinhole flowmeter of oxygen concentraror,Pinhole flowmeter of Medical oxygen concentrator,5L flowmeter for oxygen concentrator,Special firesafe Valve for oxygen concentrator,Firesafe Cannula Valve Oxygen Supply Tubing Connector,Oxygen primary filter,Medical Grade Filter,Check valve (material PA6),Check valve (material ABS),Oxygen generator accessories Molecular sieve tank head,Oxygen Concentrator Accessories Air Filters,Oxygen Concentrator Accessories NPT1/8-∅8 Connector,Oxygen Concentrator Accessories NPT1/8-∅10 Connector,Oxygen Concentrator Accessories 3 way Nozzle,Oxygen Concentrator Accessories 90° Nozzle,Mold manufacturing and i jection molding.