Innovative Applications of Solenoid Valves in Drones: Enhancing Flight Performance

With the continuous progress of technology, drones have become an indispensable part in the modern aviation field. The wide application of drones has led people to put forward higher requirements for their flight performance and safety. Under such a background, solenoid valves, as a new type of flight control device, are gradually being introduced into the field of drones and have achieved certain innovative application results.

A solenoid valve is a device that can realize fluid control by controlling electromagnetic force. Its innovative application in drones is mainly reflected in the following aspects:

First, improvement in flight stability.

The traditional drone flight control system mainly relies on mechanical actuator elements to adjust the flight attitude, while solenoid valves, as an electrically controlled actuator element, can respond to flight control instructions more precisely, thereby enhancing flight stability. By upgrading the flight control system with solenoid valves, it is possible to better deal with the complex and changeable flight environment and improve the flight stability and safety of drones.

Second, improvement in flight efficiency.

The rapid response characteristic of solenoid valves enables drones to adjust the attitude and perform actions more flexibly during the flight, thereby improving flight efficiency. Compared with traditional mechanical actuator elements, solenoid valves can control the aerodynamic force system more precisely to achieve more efficient flight performance.

Third, intelligent flight control.

Solenoid valves can be combined with modern flight control systems to realize intelligent control of the drone flight process. By collecting flight data through sensors and combining the precise control ability of solenoid valves, it is possible to realize real-time monitoring and adjustment of the drone flight process, thereby enhancing the intelligent level of the flight control system.

Fourth, reduction of structural burden.

Compared with traditional hydraulic or pneumatic actuator elements, solenoid valves have the characteristics of small volume and light weight, which can effectively reduce the structural burden of drones and improve the payload capacity and endurance time of drones. This is especially important for some application scenarios that require long flights or carrying large payloads.

In general, as a new type of flight control device, solenoid valves have broad application prospects in the field of drones. By improving and upgrading the existing drone systems and introducing solenoid valve technology, it is possible to effectively improve the flight performance and safety of drones and meet the needs of different application scenarios. With the continuous development and innovation of technology, it is believed that there will be more innovative applications of solenoid valves in the field of drones, injecting new vitality into the development of drone technology.

Product recommendation.

About us.

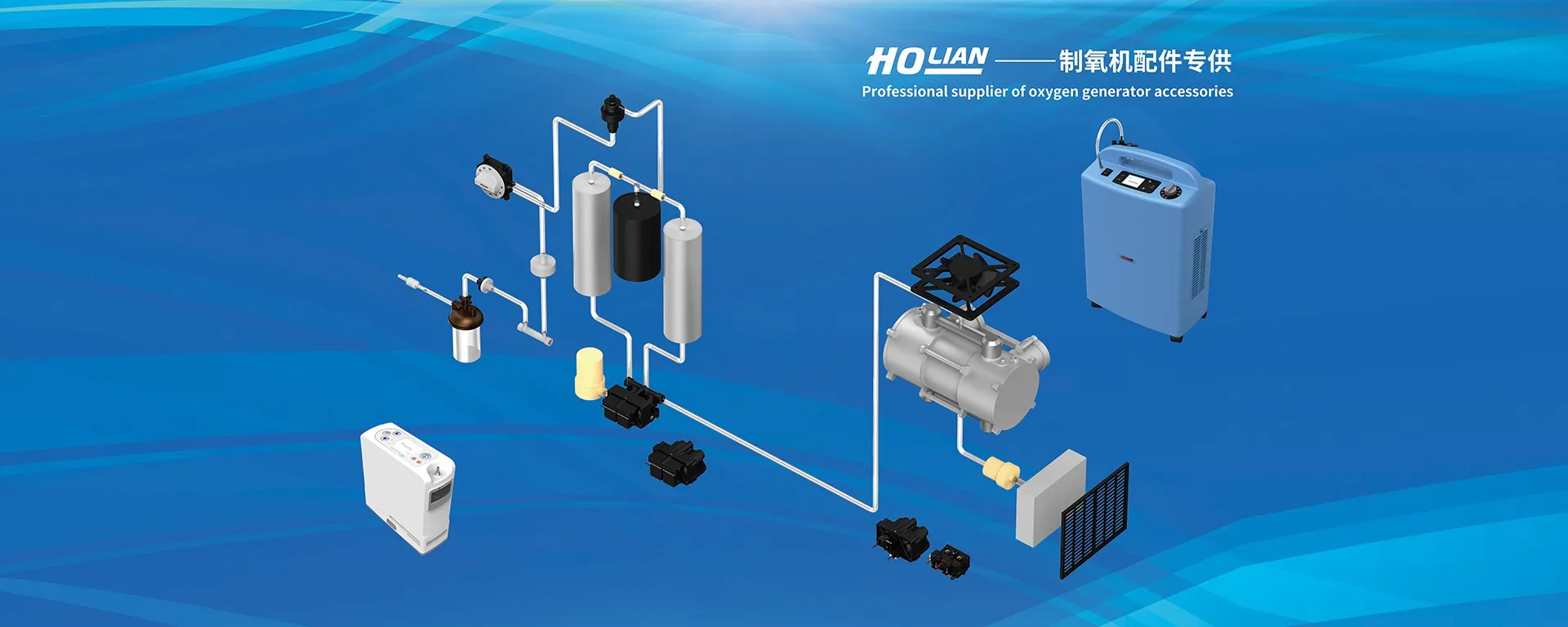

Shenyang HOlian Precision instrument co.,Ltd founded in 2017,is specialized production of oxygen generator accessories :Miniature solenoid valve for Portable Medical oxygen generator,4 Way 2 position Medical oxygen generator,3L to 10L Medical Oxygen Generator Solenoid Valve,pressure regulator assembly for oxygen concentrator,Pressure reducing Assembly for oxygen concentrator,Pinhole flowmeter of oxygen concentraror,Pinhole flowmeter of Medical oxygen concentrator,5L flowmeter for oxygen concentrator,Special firesafe Valve for oxygen concentrator,Firesafe Cannula Valve Oxygen Supply Tubing Connector,Oxygen primary filter,Medical Grade Filter,Check valve (material PA6),Check valve (material ABS),Oxygen generator accessories Molecular sieve tank head,Oxygen Concentrator Accessories Air Filters,Oxygen Concentrator Accessories NPT1/8-∅8 Connector,Oxygen Concentrator Accessories NPT1/8-∅10 Connector,Oxygen Concentrator Accessories 3 way Nozzle,Oxygen Concentrator Accessories 90° Nozzle,Mold manufacturing and i jection molding.