How to improve the efficiency of injection molding machines?

Injection molding machine is a common production equipment, which is widely used in various industries. The main function of the injection molding machine is to inject the heated plastic material into the mold, and then make it form the required product through cooling. How to improve the efficiency of the injection molding machine? This is a common problem for every injection molding machine operator.

1. Equipment maintenance

Maintenance is the key to keeping the injection molding machine running normally. Only by keeping the equipment clean and maintained can the operation of the injection molding machine be ensured. Regularly check the lubricating oil of the equipment to ensure the good lubrication condition of the equipment. The machine should be clean and hygienic, and the mechanical system should operate smoothly. These works should be carried out strictly in accordance with the guidelines of the equipment manufacturer.

2. Operational skills

The operator should receive training before using the equipment and master the skills of normal operation. When operating the equipment, the injection molding machine operator should master some basic skills, such as mastering the melting point temperature and injection speed, and should operate with few steps according to the requirements in the production process to improve production efficiency. When operating, strict attention should be paid to the rationality of the work procedures to ensure that each step is operated in accordance with the guidance. In addition, during the operation of the equipment, the running condition of the equipment should be always noted, and if there is a problem, it should be dealt with in time.

3. Equipment selection

The selection of injection molding machine equipment has a great impact on the cost and efficiency of the production line. Choosing equipment with excellent quality and high production efficiency is the key to ensuring production. Of course, the configuration of the equipment will affect the level of production efficiency due to different combinations. When choosing the equipment combination, it should be selected according to the production situation requirements and coordinated well with the equipment manufacturer, and select a more appropriate equipment specification within a reasonable range. Injection molding machine equipment is a long-term investment and should be carefully selected.

4. Mold design

The design of the mold directly affects the efficiency of the injection molding machine. For a reasonably designed mold, in addition to ensuring the quality of the product, low investment cost, high production efficiency, and simple process are all aspects that should be considered in the mold design. The design of the mold should consider the shape and size of the product, and should also accurately master parameters such as the melting point temperature, injection speed, and cooling time to ensure that the produced product meets the product requirements and improve production efficiency.

5. Employee training

Only trained employees can use equipment and operating skills more effectively and ensure the quality of the products produced by the injection molding machine. The operation of injection molding machine equipment requires professional personnel to operate. If the employees do not have the corresponding skills, they should receive training to improve the employees' operating skills and strengthen the employees' quality awareness, thereby improving the efficiency of the injection molding machine.

6. Quality control

In the process of production, the quality of the product should be always concerned. If there is a problem during the operation of the injection molding machine, it should be dealt with in time. In the specific production process, continuously control the quality of the product and analyze and solve the defects of the product. Ensuring the quality of the product and improving the production capacity is also one of the keys to improving production efficiency.

In general, improving the efficiency of the injection molding machine requires multi-faceted considerations and cooperation. Equipment maintenance, operating skills, equipment selection, mold design, employee training, and quality control are all important factors in improving the efficiency of the injection molding machine. Only by continuously improving these aspects can the efficiency of the injection molding machine be successfully improved.

Product recommendation.

About us.

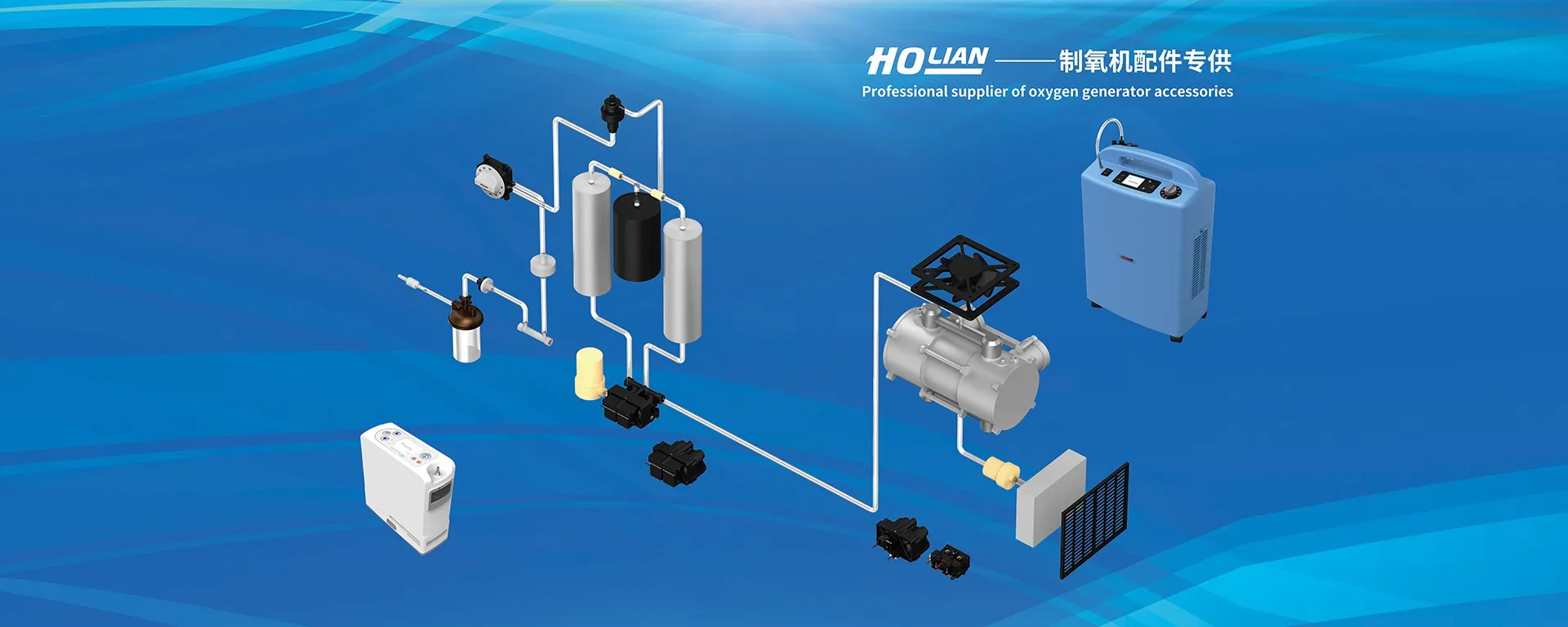

Shenyang HOlian Precision instrument co.,Ltd founded in 2017,is specialized production of oxygen generator accessories :Miniature solenoid valve for Portable Medical oxygen generator,4 Way 2 position Medical oxygen generator,3L to 10L Medical Oxygen Generator Solenoid Valve,pressure regulator assembly for oxygen concentrator,Pressure reducing Assembly for oxygen concentrator,Pinhole flowmeter of oxygen concentraror,Pinhole flowmeter of Medical oxygen concentrator,5L flowmeter for oxygen concentrator,Special firesafe Valve for oxygen concentrator,Firesafe Cannula Valve Oxygen Supply Tubing Connector,Oxygen primary filter,Medical Grade Filter,Check valve (material PA6),Check valve (material ABS),Oxygen generator accessories Molecular sieve tank head,Oxygen Concentrator Accessories Air Filters,Oxygen Concentrator Accessories NPT1/8-∅8 Connector,Oxygen Concentrator Accessories NPT1/8-∅10 Connector,Oxygen Concentrator Accessories 3 way Nozzle,Oxygen Concentrator Accessories 90° Nozzle,Mold manufacturing and i jection molding.